Off-road enthusiasts know that maintaining their equipment is crucial for a seamless and safe adventure. In this comprehensive guide, we’ll delve into the essential steps of inspecting your off-road equipment, ensuring longevity, and preventing unexpected breakdowns.

Whether you’re a seasoned off-roader or a newbie, this guide will equip you with the knowledge to keep your off-road rig in top-notch condition.

| Takeaways |

|---|

| Regular inspections prevent unexpected issues |

| Safety should be a priority during inspections |

| Visual checks and functional tests are crucial |

| Regular maintenance extends equipment life |

| Troubleshoot minor issues for on-the-trail fixes |

| Document all maintenance activities |

| Professional help is necessary for major problems |

2. Importance of Regular Equipment Inspections

Regular inspections are the key to preventing mechanical surprises on the trail. Discover why a proactive approach to off-road equipment maintenance is essential for both performance and safety.

Off-roading excitement demands safety vigilance. Learn crucial safety tips to ensure your trail adventures are thrilling and secure.

3. Safety First: Preparing for the Inspection

Before diving into the nitty-gritty of inspection, let’s prioritize safety. Equip yourself with the necessary gear and secure your work area to ensure a risk-free examination.

3.1 Safety Gear Checklist

| Gear | Purpose |

|---|---|

| Safety Glasses | Eye Protection |

| Gloves | Hand Protection |

| Ear Protection | Noise Reduction |

| Steel-toed Boots | Foot Protection |

| Reflective Vest | High Visibility |

3.2 Secure the Work Area

| Steps | Safety Measures |

|---|---|

| Mark Hazardous Areas | Highlight potential risks |

| Use Cones or Barriers | Clearly define the inspection zone |

| Emergency Contacts | Keep contact details accessible |

| First Aid Kit | Always have one on-site |

4. Visual Inspection: The First Step

Begin your inspection journey by visually assessing crucial components of your off-road equipment.

Navigate challenging landscapes with confidence using essential safety tips. Be prepared for off-road challenges and enhance your driving skills for a safer and more enjoyable experience.

4.1 Exterior Components

| Component | Inspection Points |

|---|---|

| Body and Frame | Check for cracks, dents, or rust |

| Lights and Signals | Ensure all lights are functional |

| Winch and Bumper | Inspect for any signs of damage |

| Exterior Fasteners | Tighten or replace as needed |

4.2 Fluid Levels

| Fluid | Checkpoints |

|---|---|

| Engine Oil | Verify level and condition |

| Transmission Fluid | Check for proper levels and clarity |

| Brake Fluid | Inspect the level and color |

| Coolant | Ensure it’s at the recommended level |

4.3 Tire Inspection

| Aspect | Inspection Criteria |

|---|---|

| Tread Depth | Measure and ensure it meets safety standards |

| Tire Pressure | Check for proper inflation |

| Sidewall Damage | Inspect for cuts, bulges, or punctures |

| Spare Tire | Ensure it’s in good condition and properly secured |

4.4 Suspension System

| Component | Inspection Points |

|---|---|

| Shocks and Struts | Look for leaks or damage |

| Bushings and Joints | Inspect for wear and tear |

| Springs | Ensure they are intact and functional |

| Steering Linkages | Check for tightness and proper alignment |

4.5 Brake Check

| Component | Inspection Criteria |

|---|---|

| Brake Pads and Discs | Measure thickness and check for wear |

| Brake Lines | Inspect for leaks or corrosion |

| Brake Fluid | Ensure it’s at the recommended level |

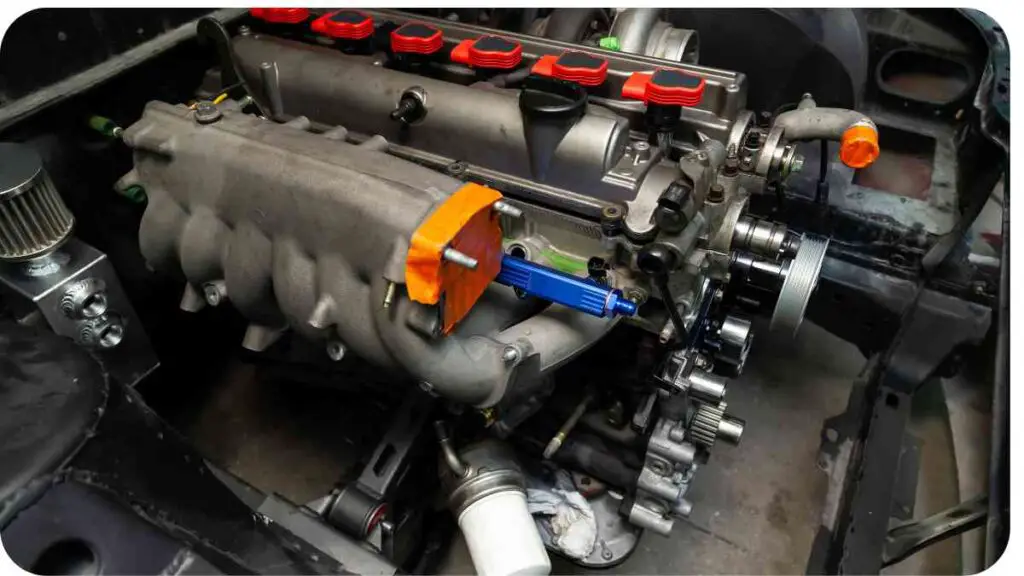

5. Functional Checks: Ensuring Optimal Performance

After the visual inspection, dive into functional checks to guarantee your off-road equipment’s optimal performance.

Keep your off-road machine running smoothly with our comprehensive oil change guide. Discover step-by-step instructions for a hassle-free DIY oil change, ensuring peak performance on every adventure.

5.1 Engine Performance

| Aspect | Inspection Criteria |

|---|---|

| Starting and Idling | Check for smooth starts and steady idling |

| Acceleration | Ensure responsiveness and smooth acceleration |

| Exhaust Emissions | Inspect for unusual smoke or odors |

| Fluid Leaks | Look for any signs of leaks under the hood |

5.2 Transmission and Drivetrain

| Component | Inspection Points |

|---|---|

| Transmission Fluid | Ensure proper levels and clarity |

| Clutch System | Check for smooth engagement and disengagement |

| Driveshaft | Inspect for any unusual vibrations |

| Axles and CV Joints | Look for signs of wear and tear |

| Differential Fluid | Verify levels and condition |

5.3 Steering Mechanism

| Component | Inspection Criteria |

|---|---|

| Power Steering Fluid | Check for proper levels and condition |

| Steering Linkages | Inspect for tightness and proper alignment |

| Steering Wheel Play | Ensure minimal play and responsiveness |

5.4 Electrical System

| Aspect | Inspection Points |

|---|---|

| Battery | Check voltage levels and secure connections |

| Wiring and Connections | Inspect for frays, corrosion, or loose connections |

| Lights and Signals | Ensure all are functional, including indicators and headlights |

5.5 Exhaust System

| Component | Inspection Criteria |

|---|---|

| Muffler and Tailpipe | Check for damage or rust |

| Exhaust Leaks | Inspect for any signs of leaks or unusual noises |

6. Advanced Inspections: Digging Deeper

Now that the visual and functional checks are complete, it’s time to take a closer look at your off-road equipment. Advanced inspections involve examining undercarriage components and utilizing diagnostic tools.

Elevate your off-road experience by prioritizing regular maintenance. Explore the key steps and benefits of keeping your vehicle in top condition for optimum performance on and off the trail.

6.1 Undercarriage Examination

| Component | Inspection Points |

|---|---|

| Skid Plates | Inspect for damage and proper attachment |

| Suspension Components | Examine for wear, leaks, or damage |

| Steering Linkages | Check for any signs of stress or deformation |

| Fluid Leaks | Look for leaks from the transmission, engine, or differential |

6.2 Diagnostic Tools and Equipment

| Tool | Purpose |

|---|---|

| OBD-II Scanner | Check for engine codes and performance data |

| Tire Pressure Gauge | Ensure accurate tire pressure readings |

| Multimeter | Test electrical components and circuits |

| Compression Tester | Assess engine compression levels |

6.3 Common Off-Road Equipment Issues

| Issue | Possible Causes | Solutions |

|---|---|---|

| Overheating | Insufficient coolant, radiator issues | Check coolant levels, inspect the radiator |

| Poor Off-Road Traction | Worn-out tires, insufficient tire pressure | Replace tires, adjust pressure |

| Suspension Problems | Damaged shocks or springs | Replace damaged components |

| Electrical Malfunctions | Faulty wiring or connections | Inspect and replace damaged wiring, connectors |

7. Regular Maintenance Tips

Preventive maintenance is key to extending the life of your off-road equipment. Implement these regular maintenance tips to keep your rig in peak condition.

7.1 Fluid Changes and Top-ups

| Fluid | Maintenance Frequency |

|---|---|

| Engine Oil | Change every 3,000 to 5,000 miles |

| Transmission Fluid | Check and change as per manufacturer’s recommendations |

| Brake Fluid | Inspect and replace if necessary |

| Coolant | Flush and replace according to the maintenance schedule |

7.2 Lubrication Points

| Component | Lubrication Schedule |

|---|---|

| Suspension Bushings | Lubricate every 10,000 miles or as needed |

| Steering Linkages | Grease every 5,000 miles or as recommended |

| Driveshaft Joints | Lubricate every 10,000 miles or as needed |

| Hinges and Pivot Points | Regularly apply lubricant to prevent rust |

7.3 Cleaning and Rust Prevention

| Component | Cleaning and Protection |

|---|---|

| Undercarriage | Clean after off-road adventures |

| Exterior Surfaces | Wash regularly and apply rust-resistant coating |

| Electrical Connections | Keep clean and use dielectric grease |

7.4 Documentation and Record-Keeping

| Records | Information to Track |

|---|---|

| Maintenance Dates | Document each maintenance activity |

| Parts Replaced | Keep a record of replaced components |

| Issues Identified | Note any problems discovered during inspections |

8. Troubleshooting: What to Do When Issues Arise

Even with regular inspections and maintenance, issues may still occur. Learn how to troubleshoot common problems and when to seek professional help.

Maximize off-road performance by selecting the perfect tire with our comprehensive guide. Explore factors influencing tire choice and make informed decisions to conquer diverse terrains with confidence.

8.1 Identifying Warning Signs

| Warning Sign | Possible Cause | Action Required |

|---|---|---|

| Engine Misfires | Ignition or fuel system issues | Check spark plugs, fuel injectors, or seek professional help |

| Unusual Noises | Loose components or damaged parts | Inspect and tighten or replace as necessary |

| Poor Performance | Various issues including engine or transmission problems | Diagnose and address the root cause |

| Warning Lights | Electrical or engine system problems | Use OBD-II scanner to retrieve error codes and take appropriate action |

8.2 Quick Fixes on the Trail

| Issue | Temporary Solutions |

|---|---|

| Flat Tire | Use a tire repair kit or replace with the spare |

| Overheating | Turn off the engine, allow it to cool, and check coolant levels |

| Battery Issues | Jump-start with jumper cables |

| Minor Electrical Problems | Check and secure loose connections |

8.3 When to Seek Professional Help

| Situation | When to Consult a Professional |

|---|---|

| Major Mechanical Failure | Inability to resolve issues on the trail |

| Extensive Electrical Problems | Persistent electrical malfunctions |

| Unidentified Noises | Strange sounds that are challenging to diagnose |

| Significant Fluid Leaks | Continuous or severe fluid leaks |

9. Off-Road Equipment Inspection Checklist

Ensure a systematic approach to your off-road equipment inspections with this comprehensive checklist.

9.1 Pre-Inspection Preparation

- Gather safety gear and equipment

- Secure the work area

- Review the equipment’s maintenance history

9.2 Visual Inspection

- Inspect exterior components

- Check fluid levels

- Perform tire inspection

- Examine suspension system

- Conduct brake check

9.3 Functional Checks

- Assess engine performance

- Inspect transmission and drivetrain

- Examine the steering mechanism

- Check the electrical system

- Inspect the exhaust system

9.4 Advanced Inspections

- Examine undercarriage components

- Utilize diagnostic tools and equipment

- Identify common off-road equipment issues

9.5 Regular Maintenance

- Change fluids and top up as needed

- Lubricate specified points

- Clean and prevent rust

- Document all maintenance activities

9.6 Troubleshooting

- Identify warning signs

- Implement quick fixes on the trail

- Know when to seek professional help

10. Conclusion

By following this comprehensive guide, you’ll not only ensure the longevity and optimal performance of your off-road equipment but also enhance your safety during thrilling adventures.

Regular inspections, proper maintenance, and a proactive approach to troubleshooting will keep you confidently exploring the off-road trails for years to come. Stay adventurous, stay safe!

Further Reading

- GoCodes – Equipment Inspection Guide

- Explore a comprehensive guide on equipment inspection, covering various aspects to ensure the optimal performance and safety of your off-road gear.

- Boom and Bucket – The Ultimate Heavy Equipment Inspection Checklist

- Delve into the ultimate checklist for heavy equipment inspections, providing insights into what to look for to maintain and enhance the performance of your machinery.

- Offroad-Ed – Inspecting Your ATV

- Gain valuable knowledge on inspecting your ATV with this study guide, ensuring a thorough examination for a safe and enjoyable off-road experience.

FAQs

How often should I inspect my off-road equipment?

Regular inspections are crucial for off-road equipment. Aim for a thorough inspection before each outing and a more detailed examination at least once a month.

What safety gear is essential for off-road equipment inspections?

Ensure you have safety glasses, gloves, ear protection, steel-toed boots, and a reflective vest to prioritize your safety during inspections.

Are there specific tools recommended for off-road equipment inspections?

Yes, tools like an OBD-II scanner, tire pressure gauge, multimeter, and a compression tester can aid in a comprehensive examination of your off-road gear.

Can I troubleshoot and fix minor issues on the trail?

Yes, for minor issues like a flat tire, overheating, or battery problems, you can implement quick fixes on the trail to get back on track temporarily.

When should I seek professional help for off-road equipment issues?

If you encounter major mechanical failures, extensive electrical problems, unidentified noises, or significant fluid leaks, it’s advisable to consult a professional for a thorough assessment and repairs.

Hi there! I’m Hellen James, and I’m the author of Unified Off-roads. I’ve been driving off-road for more than ten years, and I’ve had a lot of fun in that time—and a few not-so-great experiences too. But I’ve always wanted to help other people get started off-roading, so I decided to start this blog to share my knowledge with others.