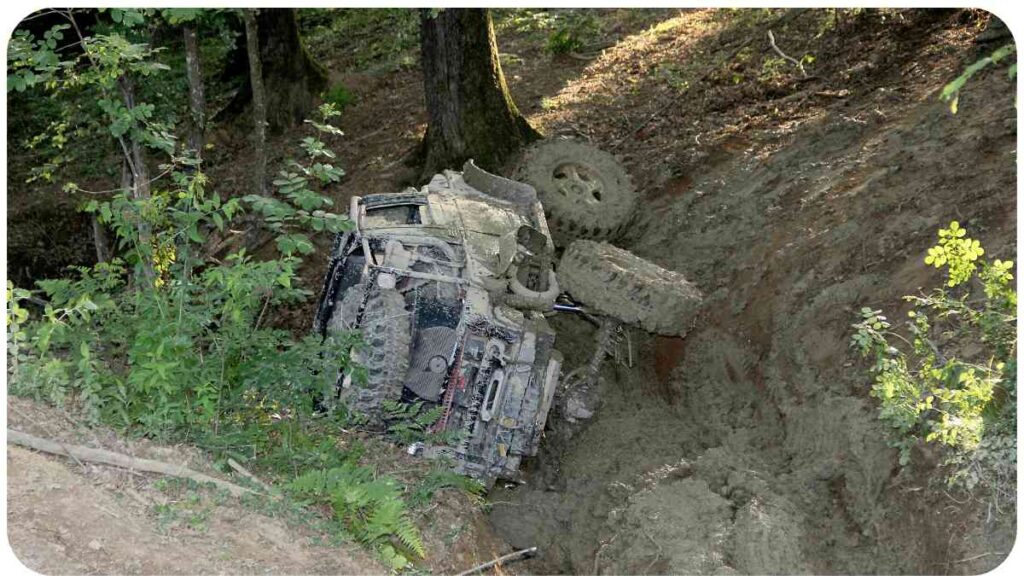

Welcome to this guide on fixing a stuck off-road vehicle winch. Off-roading adventures can take a toll on your equipment, and it’s not uncommon for winches to get stuck in various situations. In this article, we’ll walk you through common winch stuck scenarios, troubleshooting methods, and tips for winch maintenance. Whether you’re an experienced off-roader or a novice, this guide will equip you with the knowledge to handle winch issues effectively.

| Takeaway |

|---|

| Taking the necessary precautions and performing regular maintenance on your winch can help prevent it from getting stuck while off-roading. |

| Understanding common winch stuck scenarios such as jammed cables, motor failure, overheating, and electrical system issues can help you troubleshoot and resolve these problems effectively. |

| Properly inspecting your winch before and after each off-roading trip, cleaning the winch drum and cooling vents, and lubricating the components as recommended by the manufacturer are essential maintenance practices. |

| Following proper winch usage techniques, using winch line dampeners, and carrying necessary recovery gear can minimize the chances of winch stuck situations. |

| If faced with complex winch issues or unsure about repairs, consulting a professional is recommended to avoid further damage or electrical hazards. |

2. Understanding Off-Road Winches

Before diving into troubleshooting and solutions, let’s briefly understand the basics of off-road winches. These powerful devices are used to pull or lift heavy loads, offering assistance when a vehicle is stuck, stranded, or in need of recovery.

A winch typically consists of a drum, cable/wire rope, motor, and control system. When selecting a winch, factors like pulling capacity, line speed, and durability should be considered based on the weight and type of vehicles you’ll encounter in your off-road adventures.

Building a support system after experiencing grief and loss can be difficult, but finding strength in the community can make a big difference. Check out our guide on building a support system after a loss to learn more about the benefits of the community during times of grief.

3. Common Winch Stuck Scenarios

To understand how to fix a winch, it’s crucial to identify the scenarios that can cause it to get stuck. Here are the most common winch stuck situations:

3.1. Jammed Cable/Wire Rope

One of the commonly encountered issues is a jammed cable or wire rope. This can happen when the cable gets tangled, kinked, or wrapped around the drum improperly. A jammed cable prevents proper spooling, making it impossible for the winch to pull or release the cable.

3.2. Motor Failure

Another scenario is motor failure. The winch motor may stop working due to various reasons such as overheating, low battery voltage, or worn-out brushes. If the motor doesn’t function properly, it hinders the winch’s ability to function.

3.3. Overheating

Winches generate heat during operation, but excessive heat can lead to internal components failure. Overheating might occur due to prolonged usage without cool-down periods, heavy loads, or operating in challenging conditions. It’s essential to monitor the winch’s temperature and prevent overheating issues.

3.4. Electrical System Issues

Electrical system problems, such as bad connections, blown fuses, or faulty solenoids, can also cause winch malfunctions. When the electrical components fail, the winch may not respond to control inputs or may not operate at all.

Now that we’ve identified common winch stuck situations, let’s explore troubleshooting methods and solutions.

4. Troubleshooting and Solutions

In this section, we’ll look at various winch stuck scenarios and provide step-by-step solutions for each.

4.1. How to Fix a Jammed Cable/Wire Rope

When dealing with a jammed cable or wire rope, follow these steps:

- Release the tension on the winch by putting the vehicle in neutral and engaging the winch’s free spool mode.

- Inspect the cable or wire rope for knots, kinks, or tangles. If any are present, gently untangle by hand or with a winch line damper.

- If the cable is wrapped around the drum incorrectly, carefully release the cable and ensure it spools evenly.

- Lubricate the cable or wire rope regularly to prevent future issues.

Navigating through muddy terrain can be challenging, but with the right knowledge, you can conquer it. Our article on off-road driving in mud provides valuable tips and techniques to help you handle muddy obstacles effectively.

Table 1: Recommended Lubricants

| Brand | Type | Application |

| Brand A | Synthetic lubricant | Cable/Wire rope |

| Brand B | Heavy-duty grease | Winch drum |

| Brand C |

| Type | Type Explanation |

| Synthetic lubricant | These lubricants are specifically formulated to reduce friction and provide excellent protection for cables and wire ropes. They offer better resistance against wear, rust, and corrosion. |

| Heavy-duty grease | Heavy-duty greases are thick and provide long-lasting lubrication. They are ideal for coating winch drums, which are subject to high loads and frequent spooling. |

4.2. Steps to Address Motor Failure

Motor failure can be a frustrating issue, but here’s what you can do to fix it:

- Start by checking the battery voltage. Weak batteries can strain the winch motor’s performance. Ensure the battery is fully charged or replace it if necessary.

- Inspect the brushes in the winch motor. Worn-out brushes can result in motor failure. If you notice any signs of wear or damage, replace them following the manufacturer’s instructions.

- Examine the wiring connections between the motor and control system. Loose or corroded connections can cause electrical resistance, hindering proper current flow. Clean and tighten the connections to restore functionality.

- In case none of the above steps resolve the issue, it might be necessary to seek professional help to diagnose and repair the motor.

4.3. Overheating Prevention and Recovery

To prevent overheating, follow these tips:

- Avoid long periods of continuous winching. Allow the winch motor to cool down after intense use. This prevents excessive heat build-up.

- If you notice the winch becoming too hot during operation, cease winching and let it cool. Consider using an auxiliary cooling system or fans to assist in heat dissipation.

- Regularly inspect and clean the winch’s cooling vents. Dust, debris, or mud may accumulate on the vents, obstructing airflow and contributing to overheating issues.

When venturing into off-road adventures, it’s crucial to prioritize safety, especially when facing dangerous terrains. Our resource on navigating dangerous terrain offers essential safety tips to minimize risks and ensure a secure off-road experience.

4.4. Dealing with Electrical System Problems

When faced with electrical system problems, follow these troubleshooting steps:

- Check all electrical connections and ensure they are tight and free from corrosion.

- Inspect and replace any blown fuses if necessary. It’s important to use the correct fuse ratings recommended by the winch manufacturer.

- Test the solenoids using a multimeter to ensure they are functioning correctly. Faulty solenoids can impede the winch’s operation and may need to be replaced.

Remember, if you are unsure about any electrical repairs, it’s best to consult a professional to avoid further damage or electrical hazards.

5. Maintaining Your Off-Road Winch

Proper maintenance can significantly extend the life of your winch and help prevent it from getting stuck. Here are some essential maintenance tips:

- Regularly inspect the winch cable or wire rope for signs of wear, including fraying or kinks. Replace them if necessary.

- Clean the winch drum and remove any dirt, debris, or built-up mud that may hinder smooth spooling.

- Keep the winch control system clean and protected from moisture and dirt.

- Lubricate the winch components as recommended by the manufacturer to ensure smooth operation and prevent corrosion.

Remember to always refer to your winch’s user manual for specific maintenance instructions based on the model and brand.

Exploring different off-road terrains, such as rocks and sand, requires specific techniques and knowledge. Discover valuable insights and tips on off-road driving on different terrains to enhance your off-road capabilities and adapt to diverse environments.

6. Tips for Preventing Winch Stuck Situations

Prevention is the key to avoiding winch stuck scenarios. Here are some valuable tips to help you prevent winch issues:

- Practice proper winch usage techniques and avoid overloading the winch beyond its capacity.

- Use a winch line dampener when winching to prevent cable snap-back accidents.

- Carry essential recovery gear, including gloves, shackles, snatch blocks, and tree protectors, to ensure you can safely and effectively use your winch in various situations.

- Inspect your winch regularly and perform routine maintenance to catch any potential issues early on.

By following these tips, you can minimize the chances of encountering winch problems during your off-road adventures.

7. Frequently Asked Questions (FAQs)

7.1. How often should I inspect my winch?

It’s recommended to inspect your winch before and after each off-roading trip. Regular inspections help identify any potential issues before they worsen and ensure your winch is in optimal working condition.

7.2. Can I fix a winch myself, or do I need professional help?

Simple issues like jammed cables, minor electrical problems, or routine maintenance tasks can often be handled by individuals with some mechanical aptitude. However, for more complex winch problems or if you are unsure, it’s best to consult a professional for expert assistance.

8. Conclusion

When your off-road vehicle winch gets stuck, it can be frustrating and challenging. However, with the right knowledge and understanding, you can overcome these obstacles and get back on the trail. In this article, we explored common win

winch stuck scenarios, including jammed cables, motor failure, overheating, and electrical system issues. We provided step-by-step solutions to address these problems and shared tips for preventive maintenance.

To make it easier for you to understand, here’s a summary table of the common winch stuck scenarios and their corresponding solutions:

Table 2: Winch Stuck Scenarios and Solutions

| Scenario | Solution |

| Jammed Cable/Wire Rope | 1. Release tension and inspect for knots, kinks, or tangles<br>2. Untangle by hand or with a winch line damper<br>3. Ensure even spooling |

| Motor Failure | 1. Check battery voltage and replace if necessary<br>2. Inspect and replace worn-out brushes<br>3. Clean and tighten wiring connections |

| Overheating | 1. Avoid prolonged winching and allow for cool-down periods<br>2. Use auxiliary cooling systems or fans<br>3. Clean cooling vents |

| Electrical System | 1. Check and tighten electrical connections<br>2. Replace blown fuses as needed<br>3. Test solenoids for proper functioning |

In addition to troubleshooting, we discussed the importance of winch maintenance and provided tips for keeping your winch in optimal shape. Regular inspections, proper cleaning, and lubrication are essential practices to ensure your winch operates smoothly.

Lastly, to prevent winch stuck situations, we shared valuable tips such as practicing proper winch usage techniques, using winch line dampeners, and carrying the necessary recovery gear. These precautions can significantly reduce the likelihood of encountering winch issues on your off-road adventures.

By following the advice in this article and being proactive in maintaining your off-road winch, you can overcome winch stuck scenarios with confidence and continue enjoying your off-roading experiences. Stay prepared, stay safe, and have a great time exploring off the beaten path!

Further Reading

Here are some additional resources that provide further information on fixing winch issues and dealing with off-road vehicle recovery:

- No Winch? No Problem: 4 Ways to Recover a Stuck Vehicle: This article offers alternative methods for vehicle recovery when you don’t have a winch available. It covers techniques like using traction devices, winch anchors, and manual labor to get unstuck.

- How to Get Unstuck When Off-Roading: A Guide: This guide provides helpful tips and techniques for getting your off-road vehicle unstuck from various situations. It covers topics such as assessing the situation, using recovery gear, and winching techniques.

- How to Untangle a Stuck Winch Cable: This blog post offers step-by-step instructions on untangling a stuck winch cable. It provides practical tips and techniques to safely and efficiently resolve a jammed winch cable issue.

These resources can provide additional insights and guidance to supplement the information provided in this guide.

FAQs

Here are some frequently asked questions related to winch issues and their respective answers:

How often should I inspect my winch?

Regular inspections are recommended both before and after each off-roading trip. This helps identify any potential issues before they worsen and ensures your winch is in optimal working condition.

Can I fix a winch myself, or do I need professional help?

Simple issues such as jammed cables, minor electrical problems, or routine maintenance tasks can often be handled by individuals with some mechanical aptitude. However, for more complex winch problems or if you are unsure, it’s best to consult a professional for expert assistance.

What are some common signs of motor failure in a winch?

Signs of motor failure can include the winch not responding or operating correctly, unusual noises or vibrations coming from the motor, or a complete lack of power. If you suspect motor failure, it’s essential to diagnose the issue and determine if repair or replacement is necessary.

How can I prevent my winch from overheating?

To prevent winch overheating, it’s important to avoid prolonged winching without cool-down periods. Allow the winch motor to rest and cool down after intense use. You can also consider using auxiliary cooling systems or fans to assist in heat dissipation.

What should I do if my winch cable becomes jammed?

If your winch cable becomes jammed, first release the tension and inspect the cable for knots, kinks, or tangles. Gently untangle by hand or with a winch line damper, ensuring even spooling. Properly lubricating the cable regularly can also help prevent jamming issues in the future.

These questions cover a range of common concerns related to winch maintenance, troubleshooting, and prevention of winch stuck situations.

Hi there! I’m Hellen James, and I’m the author of Unified Off-roads. I’ve been driving off-road for more than ten years, and I’ve had a lot of fun in that time—and a few not-so-great experiences too. But I’ve always wanted to help other people get started off-roading, so I decided to start this blog to share my knowledge with others.